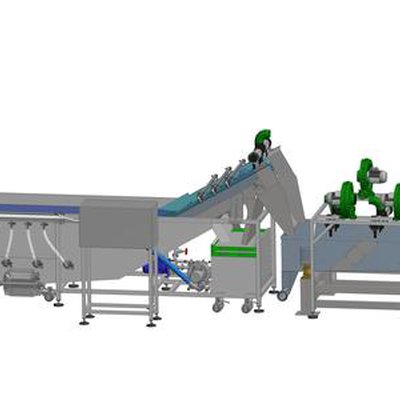

GRAPE WASHER

GRAPE WASHER

- grape washing system for a clean fermentation

GRAPE WASHER

Specialised washing system for whole grape bunches before vinification.

Grape Washer ensures complete removal of dust, leaves, heavy metals, pesticides, and other residues.

The process consists of three stages:

1. immersion washing,

2. rinsing,

3. drying.

Read more

- must clarification system using flotation

FLOTATOR

Operates based on the physical process of flotation and clarifies must using real-time turbidity monitoring. The machine separates liquid and suspended particles based on their density differences. While particles settle to the bottom during decantation, they rise to the top during flotation, forming a light sediment. This is possible because the partic…

- ion exchange resins for pH adjustment and demineralisation of must and wine

MMpH

Advanced system for precise pH reduction and partial demineralisation of must and wine using ion-exchange resins. MMpH enables gentle pH correction without altering wine balance. The system automatically manages the process until the desired pH value is reached, as defined by the operator. With the optional BLEND DEVICE, this unit can mix treated and u…

- maintaining and enhancing wine aroma during fermentation

AROMALOC®

Patented membrane technology designed to reduce the loss of volatile aromatic compounds during fermentation. The system operates in the headspace above the must, capturing aroma molecules that would otherwise escape with the CO₂ release and returning them to the wine. This maintains natural aromatic intensity and enhances varietal expression. AROMALOC®…

- mechanical microbubble gas injection into the wine flow

GAS-MIXER

Gas dosing device that mixes gases evenly with wine or other beverages. Operating in continuous flow, it ensures a uniform and controlled supply of gas directly into the liquid stream. Inside is a sintered stainless-steel filter that creates microbubbles of gas. This maximises contact between the gas and liquid phases. The result: rapid, stable dissolution of CO₂ or O₂ without over-aeration or loss of aroma. GAS-MIXER is equipped with a viewing windo…

- automatic adjustment of dissolved O₂ and CO₂ in wine

MMR-PLUS

Precisely regulates oxygen (O₂) and carbon dioxide (CO₂) levels in wine, without any impact on the taste, colour or aroma of the wine. It is designed for de-oxygenation, gas addition, and CO₂ balance adjustment in white, rosé, and red wines - from fermentation to bottling. It helps to remove excess oxygen, add CO₂ for a refreshing effect and create the right pressure for producing perlé win…

- controlled oxygenation for barrel-aged wines

OXYDUE BARRIQUE®

A portable system for precise oxygen dosing in wine barrels. In just a few minutes, it provides the oxygen needed for proper ageing management and mild aeration. It can also be used for macro-oxygenation of must. This system helps stabilise colour, soften tannins, and prevent reductive aromas during barrel ageing. <…

- controlled oxygenation for must and wine

MACRODUE®

Portable equipment for precise oxygen dosing during different winemaking stages. It can be used for macro- and meso-oxygenation, hyper-oxygenation, or to correct reductive aromas in wine. For macro-oxygenation of small volumes of wine, use MICRODUE®PLUS. More information you can find here…

- micro-oxygenation system for must and wine

MICRODUE®PLUS

A patented system for precise micro-dosing of oxygen in wine and must. It provides stable and gentle gas delivery through a calibrated volumetric piston. This has become a benchmark for accurate oxygenation in modern winemaking. MICRODUE®PLUS is operated via an intuitive touchscreen panel, allowing control of oxygen flow and duration for each injection …

- for hygienically pure air in production

AIROCIDE®

Air purification system based on NASA-developed photocatalytic technology. As air passes through the unit, organic molecules, including mould, bacteria, viruses, and odours, - are instantly converted into harmless water vapour and oxygen. It removes up to 99.999% of airborne contaminants in a single pass, keeping the air sterile and the environment safe. Read more

- 3 laboratory systems for filterability testing and filtration quality control

Q.F.T.

Q.F.T. is a range of laboratory systems designed to test and monitor the quality of liquid filtration, mainly for wine and beverages. It helps determine product filterability, membrane fouling, and key filtration parameters - FI, MFI, and Vmax. These indicators allow to optimise filtration setup and extend filtering equipment life. Q.F.T. LINE MODELS

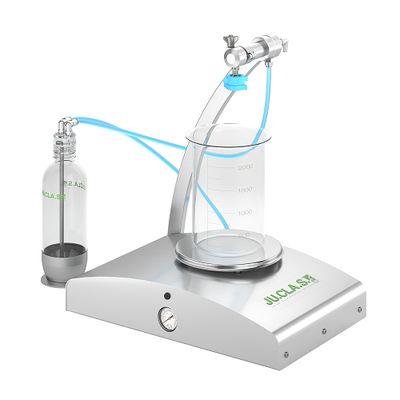

- laboratory system for wine filterability testing

MASTERMIND Q.F.T.

A laboratory equipment that measures wine filterability and water fouling index. It automatically calculates all key parameters with high precision, using integrated scales and temperature monitoring. The system helps winemakers understand how wine behaves during filtration and optimise their processes to prevent filter clogging. Results can be saved, …

- gentle wine alcohol reduction system

MASTERMIND® REMOVE

Lowers the alcohol level in wine while preserving its colour, aroma, and texture. The process uses inert membranes that extract only the alcohol - without filtering or altering the wine’s structure. It runs at room temperature, without oxygen exposure, ensuring the wine stays fresh and stable. The result is a more balanced, elegant wine that meets market trends and legal standards. FEA…

- dosing system for gum arabic and CMC; final wine treatment

DOSARABAN®

Automatic system designed for the precise dosing of both gum arabic and CMC onto microfiltration or bottling lines. It ensures a sterile and consistent application process, which maintains wine quality and prevents microbiological contamination. The system can also handle other enological liquids, such as tannins and enzymes, with the same level of accuracy and control. Read more

- dosing system for adjuvants and liquids

DOSACOM®

A fully automated system for the precise and consistent dosing of adjuvants and process liquids in winemaking and beverage production. It ensures the precise and consistent dosing of fining, cleaning or sanitising agents, making more efficient use of these products and improving process efficiency. Operating at flow rates of up to 50,000 L/h, the system is adaptable to various applications,…

- filtration and product recovery from wine sediments

SMART®LEES

A passive cross-flow filtration system that can recover up to 97% of the product from sediment, foam and filtration residues, maintaining its chemical and organoleptic properties in the process. Operating on ceramic membranes that are resistant to contamination, the device uses low pressure to prevent heating, darkening and alcohol loss. It is fully automated, requires minimal operator intervention and is suitable for long-term continuous operatio…

- microfiltration and filtration process control

SOFOS

Is a fully automatic system for cold treatment of wines and beverages through microfiltration. SOFOS controls every stage of the filtration process, from operation to cartridge regeneration and sanitisation. The system monitors parameters in real time and synchronises with filling lines and other equipment. Each operation is automatically controlled and stored in memory to ensure complete traceability and safety. Read more

- orthogonal microfiltration for still and sparkling wines

MMF

Orthogonal microfiltration system designed for wine clarification and microbiological stabilisation of still and sparkling wines. MMF supports single- and double-stage configurations, includes CIP washing, and features an extremely compact design. Filtration is gentle, preserving the wine’s aroma, texture, and colloidal balance. It automatically controls flow and pressure, ensuring precision and consistent performance.

- gentle final wine microfiltration

MFTS

High-precision tangential microfiltration system, designed to preserve the wine’s natural balance of flavour, aroma, and structure. It uses fully inert membranes, ensuring no alteration to wine composition while removing only suspended particles. This gentle process maintains colloids responsible for mouthfeel and aroma. With advanced flow management (J/DP system) and automatic cleaning cycles, MFTS delivers perfect polishing filtration without he…

- universal microfiltration for all production stages

MFTC

Advanced tangential microfiltration system for must and wine. It features next-generation hollow-fibre membranes that are highly resistant to chemical and mechanical stress while remaining completely inert to wine. Perfect for must, post-fermentation wines, clarified and sparkling wines, as well as autoclave loading. Ensures precise, stable filtration with balanced backwashing and automatic temperature control,…

- reverse osmosis for water purification and demineralisation

JROH

A range of reverse osmosis systems to produce clean, demineralised water for winemaking and food industry applications. These systems efficiently remove salts, minerals, and other impurities, ensuring consistent water quality for production processes and CIP washing. Equipped with high-quality membranes and optimised pressure control, JROH offers high output, low energy consumption, and long-lasting reliability. BENEFITS<…

- reverse osmosis for optimising wine and must composition

JRO

This mashine is designed to concentrate and balance must using reverse osmosis membranes. It allows winemakers to adjust the composition and density of must, improving balance, aroma, and structure in every vintage. With high-efficiency membranes and optimized flow and pressure control, JRO delivers excellent yield, low energy consumption, and gentle product treatment without compromising quality. This technology is particularly valuable in years …

– yeast rehydration and oak compounds extraction

EASYFERM® OAK

The new version of the EASYFERM® system. Designed for yeast rehydration and the extraction of aromatic and phenolic compounds from oak and other wooden materials, such as chips and fragments. The "OAK Function" makes the ageing process simpler and faster. In contrast to the traditional method of soaking oak pieces in the tank for a long time, EASYFERM® OAK automates the process by controlling circulation, time and temperature. The system is fully compatib…

- automatic yeast rehydration

EASYFERM

The first automatic system designed to rehydrate and precondition dry yeast ready for fermentation. Healthy fermentation depends on yeast vitality, and EASYFERM provides the perfect temperature and mixing conditions to safely and efficiently reactivate the cells. This system guarantees a clean, strong and reliable start to fermentation. It is suitable for white, rosé and red wines, as well as re-fermentations and restarting stuck fermentations. <…

- must flotation system

EASYFLOAT

A compact and high-efficiency system for must flotation during transfer over on tanks. Gas is dissolved under pressure in a stainless-steel cylinder, creating fine bubbles that lift suspended solids and quickly clarify the must. It can operate with air or nitrogen, making it suitable for traditional, hyper-oxygenation, or reductive winemaking. EASYFLOAT includes a full electrical control panel and all …

FLOTATOR

FLOTATOR

MMpH

MMpH

AROMALOC®

AROMALOC®

GAS-MIXER

GAS-MIXER

MMR-PLUS

MMR-PLUS

OXYDUE BARRIQUE®

OXYDUE BARRIQUE®

MACRODUE®

MACRODUE®

MICRODUE®PLUS

MICRODUE®PLUS

AIROCIDE®

AIROCIDE®

Q.F.T.

Q.F.T.

MASTERMIND Q.F.T.

MASTERMIND Q.F.T.

MASTERMIND® REMOVE

MASTERMIND® REMOVE

DOSARABAN®

DOSARABAN®

DOSACOM®

DOSACOM®

SMART®LEES

SMART®LEES

SOFOS

SOFOS

MMF

MMF

MFTS

MFTS

MFTC

MFTC

JROH

JROH

JRO

JRO

EASYFERM® OAK

EASYFERM® OAK

EASYFERM

EASYFERM

EASYFLOAT

EASYFLOAT