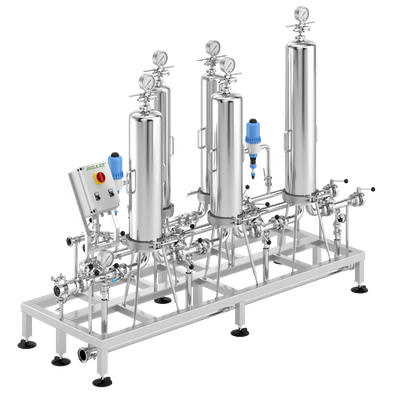

MICROFILTRAZIONE JU.CLA.S.

CONTROL PROCESS IN YOUR HANDS.

In the beverage industry, microfiltration is essential to improve and maintain the quality of the product. It improves the product by removing inorganic (particles) and organic (microrganisms) pollutants responsible for organoleptic alterations and turbidity and thus prolongs the product's shelf life.

It maintains the quality of the product by shelding it from external contaminants (from the environment, machines, utility fluids...) that may intervene in the process altering its quality.

It is important to note that the principle of microfiltration should preserve the integrity of the raw material without reducing its quality. The Vason Group is capable of providing the appropiate solutions to every single need, starting with the simplest application: the first step is the planning of the machinery's layout so as to prevent the onset of non-conformities. The second step is to choose of the microfilter cartridges will depend on the dimensions of the machinery.

CLOGGING PREVENTION AND REGENERATION PROCEDURES.

Vason Group with its cleaning division is willing to provide information on the regeneration and management of the filtering elements in general to assure the duration, efficiency of the process, and the certainly or sterilized bottles. Further in-depth information and system solutions (Q.F.T.). Are also available concerning wine filtration tests, and are indispensable in preventing early clogging of filtering elements and checking the same for the proper managementof the microfiltration processes and the preservation of the qualitative properties of wines.

ADVANTAGES

- Absolute accuracy in the construction of the facilities

- Hygienic completion of welded parts

- Personalized and safe planning of lay-outs

- Management of services (water, gas, and steam/vapour lines)

- Wide selection of accessories

- Possibility of automizing valves

- Possibility of dosing detergents and sanitizers along the productionline

- Stationary or movable machinery

- Possibility of determining the dosage of gum arabic at the end of the filtration

- Hygiene certification UNI EN 1672-2:2009